Chemical pumping service

Booster of crude oil production

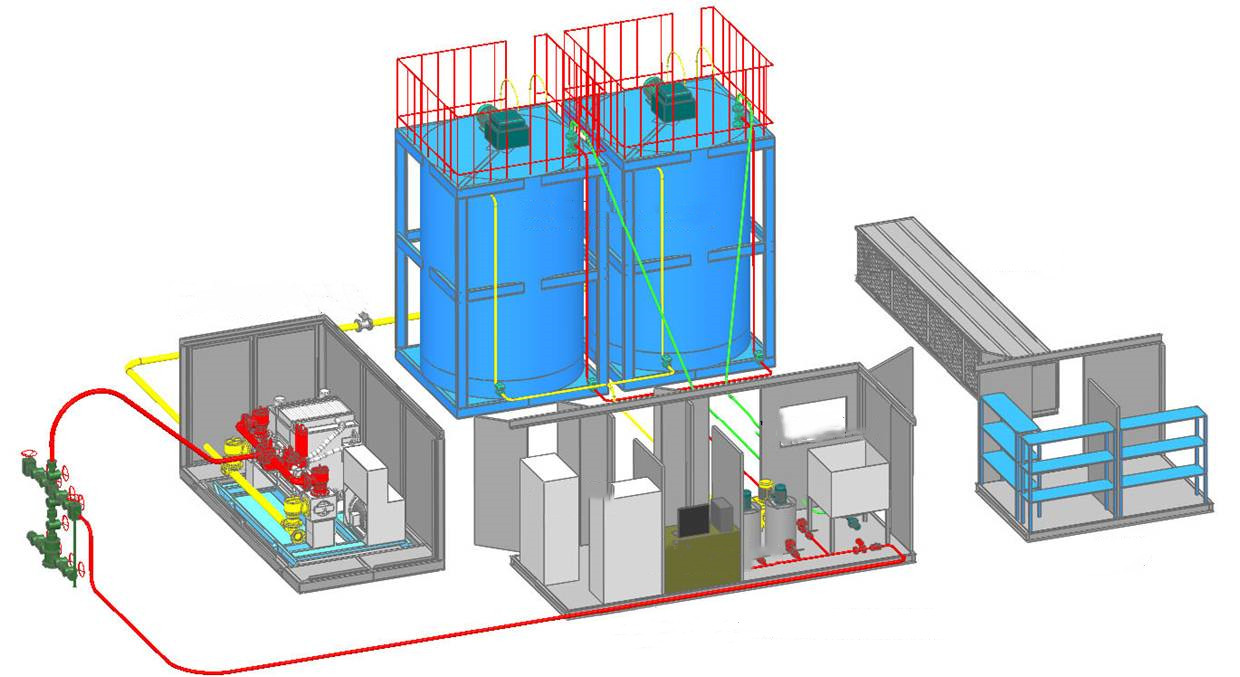

The process is used to quantitatively inject chemicals into the drilling or completion well to meet the requirements of thickening, paraffin removal, plug removal and sealing of high permeability layer, meet the normal production needs of oil (gas) wells and improve the crude oil production rate.

Chemical pumping service equipment

Features of the process

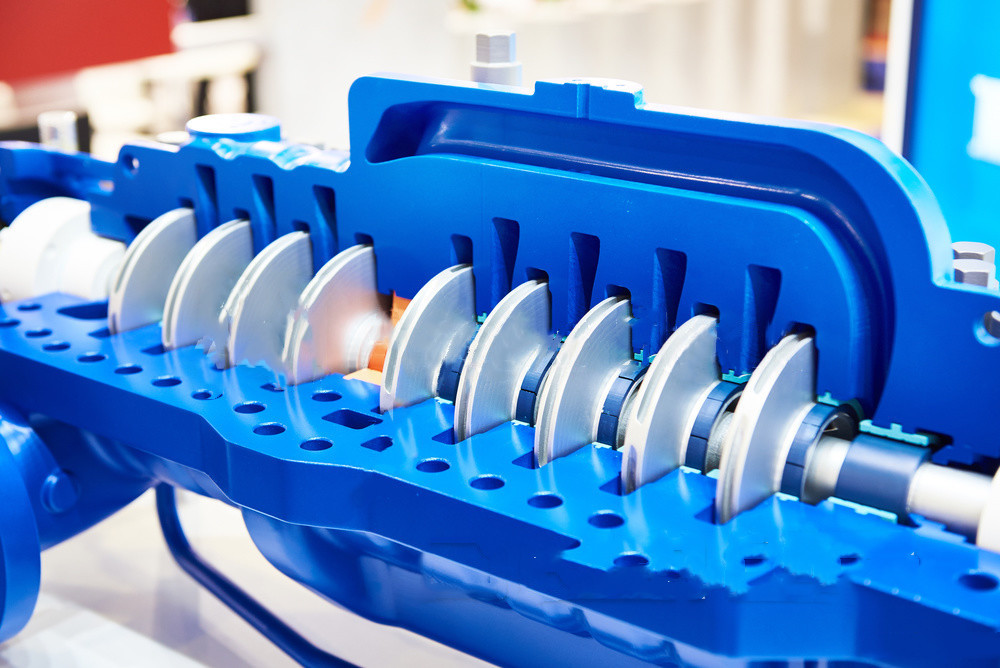

The process reagent injection pump meets the control requirements of precise injection of chemicals under high and low pressure conditions.

Pressurization mode;

Pneumatic liquid booster pump

All stainless steel structure, suitable for desert and other harsh environment.

The output pressure and flow can be easily adjusted and controlled.

It has the function of starting under pressure and can be used at the wellhead of various pressure levels.

Driving mode:

pneumatic or electric.

The large volume liquid storage tank is made of 316SS.

The coil can be designed as needed to facilitate the collection and release of pipelines.